This automation ensures your calculations are consistent and free from human errors. At the start of the year, the work-in-process inventory was $150,000, and it increased Accounting for Marketing Agencies to $250,000 by year-end. Company A employs 30 factory workers whose total salaries for the year amount to $1,800,000. Think of it as taking inventory of all the ingredients in your manufacturing recipe. Therefore, the cost of goods manufactured (COGM) for this period is $22,000. For a clearer idea of how the COGM formula works, let’s look at a hypothetical example.

Identifying Direct Materials Costs in COGM

- Remember, COGM includes all the costs of making your products, like materials, labor, and overhead.

- Another closely related KPI crucial in manufacturing accounting is the cost of goods sold or COGS.

- The ending WIP, on the other hand, comprises the remaining manufacturing costs after deducting the value of goods finished within the period.

- Then, allocate these costs to your products based on a predetermined rate, such as machine hours or labor hours.

- Calculating the cost of goods manufactured helps businesses determine the total cost incurred in producing goods ready for sale, aiding in pricing decisions and financial reporting.

- Easy to run solutions for retail and e-commerce businesses, optimizing inventory management, order fulfillment, and customer experience, driving efficiency and profitability.

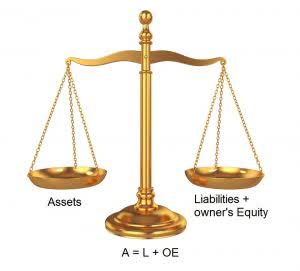

TMC calculations only include direct material costs because they do not include indirect material or factory overhead expenses. The main components of COGM are direct materials, direct labor, and manufacturing overhead. It’s essential for manufacturers to calculate COGM precisely because it directly affects pricing, cost control, profitability, and financial reporting. Accurate COGM calculation ensures competitive pricing strategies and reliable gross margins, safeguarding the financial to calculate cost of goods manufactured add health of the business. COGM is crucial to many important business decisions, such as pricing, product design, and resource allocation. For example, a company can use COGM to determine the minimum selling price needed to cover the cost of producing a product and generate a profit.

- Direct materials, such as steel used to construct automobile frames or fabric in clothing manufacturing, may be easily linked to a particular product or unit of production.

- Essentially, COGS is to finished goods inventory what COGM is to WIP inventory.

- Artificial intelligence simplifies this process by automating cost tracking, identifying pricing anomalies, and forecasting future changes.

- Without it, businesses would be in the dark about their production costs.

- If hindi agad matutugunan, these issues can lead to inaccurate financial reports, impacting strategic direction and potentially affecting profitability.

COGM in a manufacturing ERP

- While accountants can approximate its value at the end of fiscal periods, modern inventory and manufacturing software calculates COGM in real-time, based on actual manufacturing data.

- By tracking the COGM over time, a company can identify trends and patterns in its production costs and take action to reduce or control costs.

- Inventory management software like Warehouse 15 by Cleverence can streamline the entire process, saving you time and reducing the risk of errors.

- By the end, you’ll have a clear roadmap to mastering this crucial aspect of production accounting.

- Get automatic manufacturing cost calculations with Katana, including live inventory management, real-time production planning, and more essential manufacturing features.

That’s because beginning inventory of finished goods is the ending finished goods inventory from last period. If you’re calculating finished goods inventory regularly, determining beginning inventory of finished goods is typically as easy as looking at your past balance sheet. One manufacturer’s finished goods inventory may be a retailer’s merchandise inventory, dropshipping inventory, or another manufacturer’s raw material or component. The destination of these finished goods determines their classification after completion. Here’s what finished goods inventory is, how to calculate it, and why it’s one of the best types of inventory out there.

Why the cost of goods manufactured formula is important

Finally, COGM helps you identify inefficiencies in your production process. By breaking down the costs into direct materials, direct labor, and manufacturing overhead, you can pinpoint areas where you might be overspending. This allows you to make informed decisions about cost-cutting measures or process improvements. Manufacturing overhead refers to the indirect costs that a company incurs during production over a specific period. The COGM schedule is a part of the financial statement of a business that shows the total cost incurred by a company to manufacture goods during a specific period, typically a month or a year. COGM is used in the income statement of the reporting and is subtracted from sales to then calculate gross margin (the portion of a company’s revenue after direct costs have been removed).

Optimizing Manufacturing Costs

It’s like the total bill for making products, covering everything from materials to labor. Well, knowing this number helps businesses see if they’re making or losing money. TMC, conversely, comprises only the total costs of materials and labor required for production, often not including the factory overhead that COGM encompasses. Cost of goods manufactured schedule accurately provides insight into the production costs and helps ensure how is sales tax calculated that financial statements reflect the true cost of goods produced.